Industrial operations that involve constant friction, material flow, and impact demand steel that can endure severe wear without compromising strength. Rockstar 450 is developed to meet these exact requirements. Positioned between moderate and ultra-high hardness wear plates, this grade offers a strong combination of abrasion resistance and structural reliability. It is widely used in sectors where equipment is exposed to continuous stress and abrasive materials.

Body

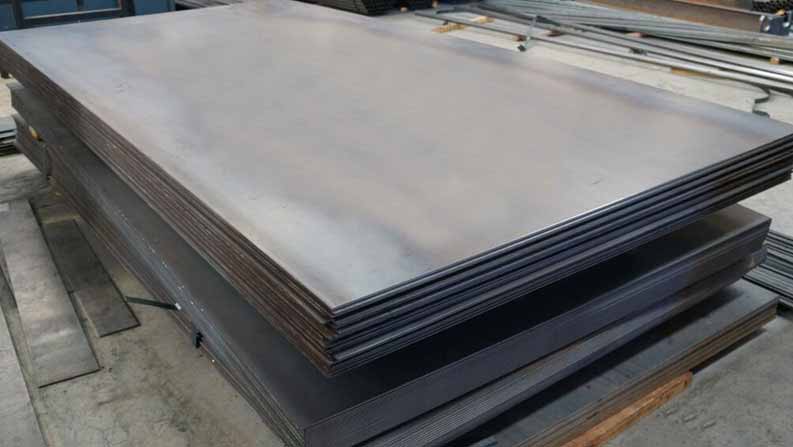

Rockstar 450 is an abrasion-resistant steel plate with a nominal hardness of approximately 450 HB. This increased hardness level provides greater protection against sliding wear and gouging compared to lower hardness grades. The steel is manufactured using controlled heat treatment processes to ensure consistent hardness across the plate thickness.

The strength of Rockstar 450 lies in its ability to reduce material loss caused by contact with harsh substances such as gravel, coal, crushed rock, and minerals. In high-wear zones, standard steel plates may fail quickly, but Rockstar 450 maintains surface integrity for extended periods. This durability directly contributes to longer equipment life and improved operational efficiency.

Despite its higher hardness, Rockstar 450 retains practical toughness. This balance allows it to perform reliably in applications involving impact loads. With suitable fabrication methods, the material can be cut, formed, and welded to create customized components. Proper handling ensures that the mechanical properties remain stable throughout the fabrication process.

By minimizing wear-related damage, Rockstar 450 helps reduce maintenance intervals and downtime. This makes it an efficient solution for industries where consistent production and equipment reliability are essential.

Key Features of Rockstar 450

Nominal hardness of approximately 450 HB

Enhanced resistance to abrasion and sliding wear

Uniform hardness throughout plate thickness

Good toughness under heavy mechanical stress

Suitable for fabrication with appropriate procedures

Extended service life in high-wear environments

These characteristics make Rockstar 450 a dependable material for demanding industrial applications.

Types of Rockstar 450

Rockstar 450 is available in several forms to meet diverse operational requirements, including:

Standard Wear Plates for general abrasion resistance

Heavy Thickness Plates for severe impact and load conditions

Cut-to-Size Plates customized for specific equipment needs

Fabricated Wear Components produced from Rockstar 450

This variety supports flexibility in design and industrial manufacturing.

Applications of Rockstar 450

Due to its strong wear resistance, Rockstar 450 is commonly used in:

Mining and quarry equipment

Excavator buckets and loader attachments

Dump truck bodies and liners

Crushers and screening systems

Conveyor chutes and transfer points

Cement and aggregate plants

Construction and earthmoving machinery

Its performance ensures durability in environments exposed to heavy abrasion and impact.

Conclusion

Rockstar 450 offers an effective balance of hardness, strength, and wear resistance for industries operating under tough conditions. Designed to handle continuous abrasion while maintaining structural reliability, it significantly extends equipment lifespan and reduces maintenance costs. For businesses seeking improved durability and dependable performance, Rockstar 450 provides a strong and practical solution.